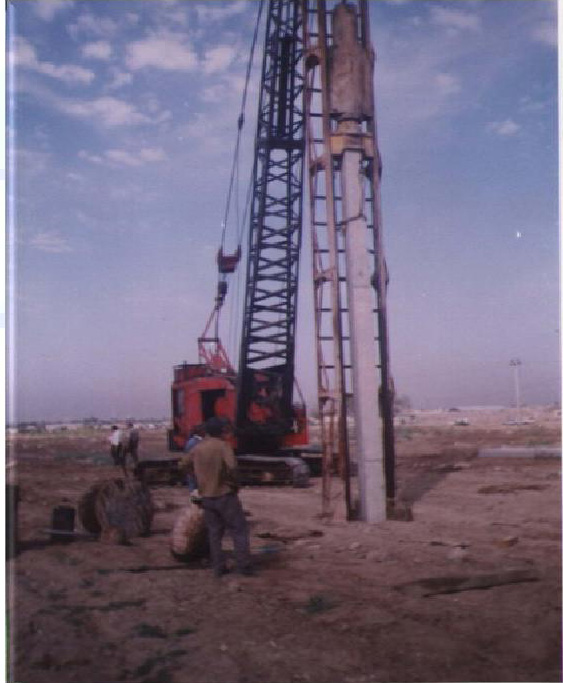

Precast Piles

Al-Saba’ precast pile is a high strength high capacity precast concrete pile which incorporates a mechanical joint, allowing piles to be spliced quickly and then driven to any required depth.

Precast piles offer the geotechnical efficiency of a driven pile with the economies of a mass produced product. A rigorous quality assurance program throughout the casting, driving and casting process ensures a consistently reliable product with high strength and durability.

Precast piles are most suited to ground conditions where soft upper strata overlie a hard bearing layer and in areas with clay or silt deposits.

Al-Saba’Co. maintains its own casting facilities which enables it to cater for varying site conditions with a range of stock pile lengths & sizes.

Al-Saba’Co. maintains in house casting capacity sufficient to customize pile lengths for individual sites and to cater for site variability without the need for long casting periods prior to job commencement.

Load Capacity

Al-Saba’Co. precast piles are manufactured from high strength concrete using state of the art technology. Structural load capacities are based on an independent testing and research program. Piles are driven using the most sophisticated piling machines operating in Australia. These are equipped with efficient hydraulic hammers for faster installation and lower pile stresses during driving. The geotechnical strength and serviceability are determined using analytical methods applicable to displacement piles and parameters based largely on intensive static and dynamic load test results.

The Pile Joint

Al-Saba’Co. uses a range of jointing systems including a pinned pile joint which priestesses the pile sections together. Pins are automatically locked in by a spring washer to ensure the full transmission of forces during driving and an anti-corrosion compound in the locking block effectively seals the area between the joint plates and the locking mechanism against water ingress. The joint is designed and proof tested to ensure that where necessary the compression, tension and bending stresses are similar to that of the pile section.